Holec

Holec

Holec started out as a partnership between HEEMAF, Smit (Slikkerveer) and Hazemeyer in 1963. Hazemeyer's reputation was made in the second world war, when its anti-aircraft guns proved superior to anything the allies had in the beginning of the war. The name is presumably a portmanteau of Holland and Electric. The partnership was a reaction on European integration. Shortly thereafter, a number of other companies, including Coq were added. Reorganisations turned the partnership into a single company, with its former partners specialising on certain products. The oil crisis and its aftermath eroded Holec's market share, leading eventually to its sale to Royal Begemann Group, an opportunistic investor. RBG took the combination apart, selling what it could sell. The remaining parts of Holec were eventually bought by a US enterprise, Eaton.

HEEMAF

The letters HEEMAF HO in the logo stand for Hengelosche Electrische en Mechanische Apparaten Fabriek (electrical and mechanical machinery factory), Hengelo in the province of Overijssel. The company was created as a technical agency in 1884 in Borne by Rento Hofstede Crull. In 1900, it moved to Hengelo and took the HEEMAF name. Due to the first world war, the company started producing its own machines. It expanded rapidly, moving from one location in Hengelo to another. The logo seen on its tokens dates from 1913. It remained in use until 1994. Its most important products were machines, engines, transformers, generators and complete systems for power stations, factories, ports, water works, rolling stock as well as telephones. In many of these markets, it was market leader or dominant producer. Its most important geographical market by far was the Netherlands, followed by the Netherlands East Indies.

In 1920, HEEMAF developed a new type of electrical engine (SKA) that gave it a worldwide comparative advantage and unprecedented access to other European markets. The illustration shows a demonstration stand in a 1928 trade fair. Picture source: Holec Historisch Genootschap (Holec historical society.) This advantage was lost in the crash of 1929 and its aftermath. When the economic tide turned, the second world war started. Post-war, even after the reconstruction of the Dutch economy, HEEMAF lacked the capital for the necessary investments, which led to its entry in Holec.

Coq

H. A. Hidde Nijland started a factory of electrical equipment in 1916. His initials HAHN spell the German word for rooster, which is coq in French. The choice to use French, rather than German during the first world war is significant. Coq produced electrical equipment for the Dutch market. Although Hidde Nijland was stridently anti-nazi, the factory came through the second world war unscathed. Coqs factory was originally at Kanaalweg 41, as illustrated. Picture source: Holec Historisch Genootschap (Holec historical society.) The adres was re-numbered to Kanaalweg 72 in the period 1950 to 1953. In this period, Coq expanded into the French market. As European integration advanced, Coq realised it was too small to survive on a European market. Hidde Nijland's death in 1962 galvanised talks with Holec, resulting in a merger in 1969. Coq remained on the same address until 1982. The factory is demolished, the land is now a parking lot.

Smit

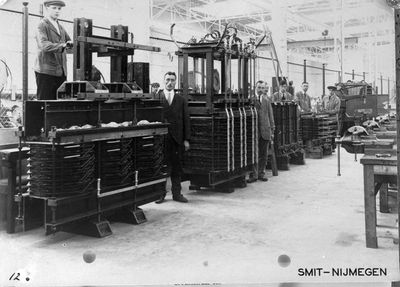

In 1882, Willem Smit and his partner Adriaan Pot started the Electrisch-Licht-Machinen Fabriek Willem Smit & Co (electric light machinery factory) in Slikkerveer, near Rotterdam. Electrification gave the company an early boost. The transformer part of the company was moved to Nijmegen in 1913 in order to acquire space for physical expansion. The picture shows a production hall in 1921. Picture source: Holec Historisch Genootschap (Holec historical society.) Child labour raised no eyebrows in those days. Due to severe trade restrictions in the first world war, the company started to produce copper wire, but otherwise, its main products remained electrical transformers. That basis was not broad enough to compete on the European market, so Smit Slikkerveer (1962) as well as Smit Nijmegen (1969) became part of Holec.

AFO

In 1936, Johan Keller, director of the Water Supply Company "Overijssel" established Apparaten Fabriek Overijssel (A.F.O. - equipment factory Overijssel) in Zwolle on Walstraat 19. At first, orders came primarily from the Water Supply Company. The company grew steadily, though, so that AFO could move to a larger building on Veerallee in Zwolle in 1939.

During the second world war, AFO was transformed into a division of the Water Supply Company to prevent workers from being sent to Nazi Germany as slave labourers. During the war, AFO developed various innovative electrical products with the materials still available. Initially, these included mainly household items such as electric timepieces, electric blankets and even toys (meccano sets). Later, windmills made from car dynamos with batteries in jam jars, so that the energy generated could be stored and used later were added. These products were so successful, that the factory had to be expanded in 1945.

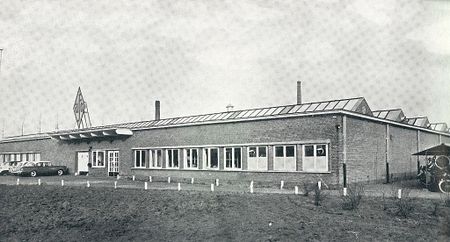

In 1948, AFO's main plant was largely destroyed by fire. AFO moved to a new complex on Populierenlaan 3 in nearby Hattem. Picture source: Holec Historisch Genootschap (Holec historical society.) The coffee tokens were used in this facility. This development inadvertently gave AFO a strong position when post-war reconstruction started. The equipment was quickly modernised, making AFO attractive for the Dutch armed forces, but also making it possible to venture into electronics. Although the armed forces orders fell back sharply in the 1960s, AFO was by that time exporting to 8 countries. Military know-how was converted to use for civilian purposes.

Yet, European integration found AFO too small and with too few markets. In 1962, AFO was acquired by Smit, which became part of Holec only a few year later. In 1971, HEEMAF took over and expanded the Hattem facility. By around 1980, the Holec divisions in Hattem moved to Apeldoorn. The plant was demolished and the land is ready for re-use.

Tokens

| Holec | ||

|---|---|---|

| ||

| Filename | HHE1 | |

| Side 1 | HEEMAF company logo | |

| Side 2 | HEEMAF company logo | |

| Manufacture | Brass | |

| Size (mm) | 20 | |

| Weight (grams) | 3.4 | |

| Notes | ||

| Source | Figleaf | |

| ||

| Filename | UCQ1 | |

| Side 1 | Company logo | |

| Side 2 | N.V./"Coq"/KANAALWEG 72/UTRECHT | |

| Manufacture | Brass | |

| Size (mm) | 20 | |

| Weight (grams) | ||

| Notes | ||

| Source | Holec Historisch Genootschap | |

| ||

| Filename | NSM1 | |

| Side 1 | Smit Nijmegen company logo | |

| Side 2 | Blank | |

| Manufacture | Brass | |

| Size (mm) | 20 | |

| Weight (grams) | 3.4 | |

| Notes | ||

| Source | Figleaf | |

| File:HAF.jpg | ||

| Filename | HAF1 | |

| Side 1 | AFO logo and natoma | |

| Side 2 | Natoma logo | |

| Manufacture | Copper-nickel | |

| Size (mm) | 22.5 | |

| Weight (grams) | ||

| Notes | ||

| Source | Kooij | |